SARAS Multi-Purpose Regional light Transport Aircraft (RTA)

BACKGROUND

After a little over 20 years and an estimated expenditure of at least Rs 1,000 crore, the ambition to have an India-made civilian transport aircraft is nowhere near completion and has morphed into a military version. Interestingly, India, is the only BRICS nation without an indigenous passenger aircraft manufacturing capability.

The project began in 1991 as a collaboration with Russia (Myasishchev had a similar projects called the M-101 Gzhel and M-102 Duet). IAF wanted to purchase 15 SARAS aircrafts to be used for Training pilots and for transport flying. NAL had also planned to develop further variants of the aircrafts to be used for coastal and aerial surveillance or develop an executive jet variant for private & business use.

ROLE

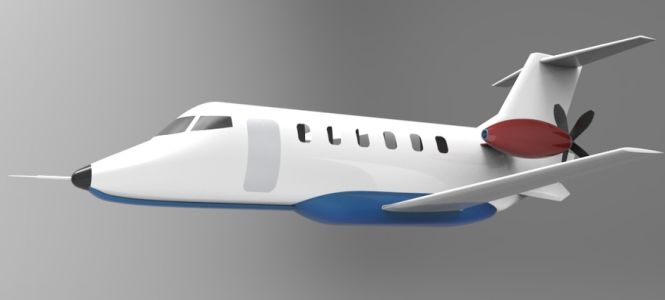

The Third Prototype Concept of SARAS Light Transport Aircraft - Image Vinoth R Kumar

NAL SARAS is an Indigenous twin-engine, multi-role light transport aircraft being designed and developed jointly by Indian Companies National Aerospace Laboratories (NAL) and Hindustan Aeronautics limited (HAL) for the Indian Air Force. It is the first Indian multi-purpose civilian aircraft in the light transport aircraft category which is designed to execute passenger and freight transport, remote sensing, flight training, aerial surveillance, coastal surveillance ,border patrolling and medical evacuation missions.

DESIGN

The SARAS was designed to fly both day and night from semi-prepared airfields and grass runways even in hostile environments. It was designed to manoeuvre in hot temperatures and high altitudes. It was designed adhering to the FAR-25/23 standard regulations and can offer air taxi and commuter services.

The Aircraft has crew capacity of 3 with the additional capacity of carrying 14 passengers in its pressurised cabin. The aircraft features a conventional all metallic fuselage and carbon fibre composite (CFC) wings. The cabin is being build to flexibly suit commuter, executive with luxury seats, executive with deluxe seats, ambulance and combat versions.

AVIONICS & COCKPIT

Airforce-Technology website reports that the SARAS will feature the latest Arinc-429 Simpatico digital avionics suite which includes CH-3100 attitude and heading reference system,TDR-94 transponder, VHF-422-B communication system, ADF-462 automatic direction finder, ALT-4000 radar altimeter, VOR-432 voice recorder and BME-442 distance measuring equipment.

SARAS is designed to be equipped with encompass air speed indicator, GPS receiver, inertial sensor unit, automatic flight control system, radio tuning unit, cockpit voice recorder and flight data acquisition unit. The glass cockpit in which two adjacent seat for pilot and co-pilot will be fitted will feature two Barco MFD 6.8/1 multifunctional displays, two primary flight displays with EFIS control panel, engine instrument display and colour weather radar display .There will be the great visibility from the all round glass canopy of cockpit to the flight crew.

ENGINE & PERFORMANCE

Pratt & Whitney Canada PT6A-67A Turboprop Engine

NAL SARAS will be powered by 2X Pratt & Whitney Canada PT6A-67A turboprop engines that are capable of producing 895 kw of thrust each. The transmission system includes epicyclic speed reduction gear box to minimize the propeller noise by optimising the output speed. The 2.65 m diameter propeller can make 1700 rpm in pusher configuration.

The aircraft has a maximum takeoff weight of 6,100 kg with the maximum speed of 550 km/h and cruise speed of 520 km/h. The maximum range is 920km with the maximum endurance of 4 hours 45 minutes. It can climb at the rate of 10.5m/sec. The ferry range and service ceiling of the aircraft will be 1,935km and 7,500m respectively.

INCIDENTS

Of the two Saras prototypes produced, the second crashed in March 2009 during a flight test, killing all three crew members. A court of inquiry found that wrong engine relight drills given to the pilots contributed to the crash, concluding that an "Incorrect relight procedure devised by the designer and adopted by the crew at insufficient height leading to rapid loss of altitude and abnormal behaviour of aircraft resulted into accident.

STATUS

In 2013 the response to an application under the national Right to Information law, on SARAS’ status, shows it is now being developed as a military aircraft. According to the response from the National Aerospace Laboratory, it has sent a draft ‘certificate of design’ for the avionics system, flight control system, hydraulics and landing gear, among other systems, to the Centre for Military Airworthiness and Certification. At the same time, clearance has been sought from the Directorate General of Aeronautical Quality Assurance for some of the systems.

While the first prototype was clearly overweight at 5,118 kg compared to the 4,125 kg design specifications the second prototype lost about 400 kg, but it was still heavy by 500 kg which is likely to be addressed in the third variant.

NAL has developed a third prototype and features a new glass cockpit, pressure bulkhead, fuselage top skin, composite tails and wings. Besides the reduction in weight, the third prototype will be upgraded to meet the latest design criteria including higher-power 1,200hp (895kW) Pratt & Whitney Canada PT6A-67A engines and improvements to the flight control and flight operations systems. According to sources, a new and enhanced technology is being applied on the wings of the SARAS aircraft. The wings, made of carbon composite, are being fabricated with a fully in-house developed technology called VERITy (Vacuum Enhanced Resin Infusion Technology).

The re-engined and modified version of the 14-seater third prototype was supposed to take off in late January 2015 but nothing was heard of it ever since.

If developed, the new aircraft will enter a crowded field, potentially competing with aircraft such as the recently certified Chinese Y-12F, Antonov An-28, Short SC.7 Skyvan, CASA C-212 Aviocar, IAI Arava and Dornier 228.

CONCLUSION

The requirements for the success of such a complex program are many, NAL/HAL must ensure execution has adequate funding support, prescribed accountability, specific delivery timelines, cost and quality targets, project monitoring, and, most important, development and production engagement with Indian private-sector firms as well as overseas institutions as there is no point in reinventing the wheel on technologies and sub-assemblies that may have already been developed elsewhere at a fraction of the cost. Efforts should be made to leverage the offsets that are available in the defense sector for building critical domestic capabilities in high-precision manufacturing and avionics.

Admin - IDN